All done under one roof.

In a world where few manufacturers have the capability to keep EMI shielding and thermal products made under one roof, the latest RF & microwave absorber line completes our advanced product offering.

Our absorbers are offered in the form of automated dispensing epoxy and cavity resonance pads. Both options offer quick-turn prototypes.

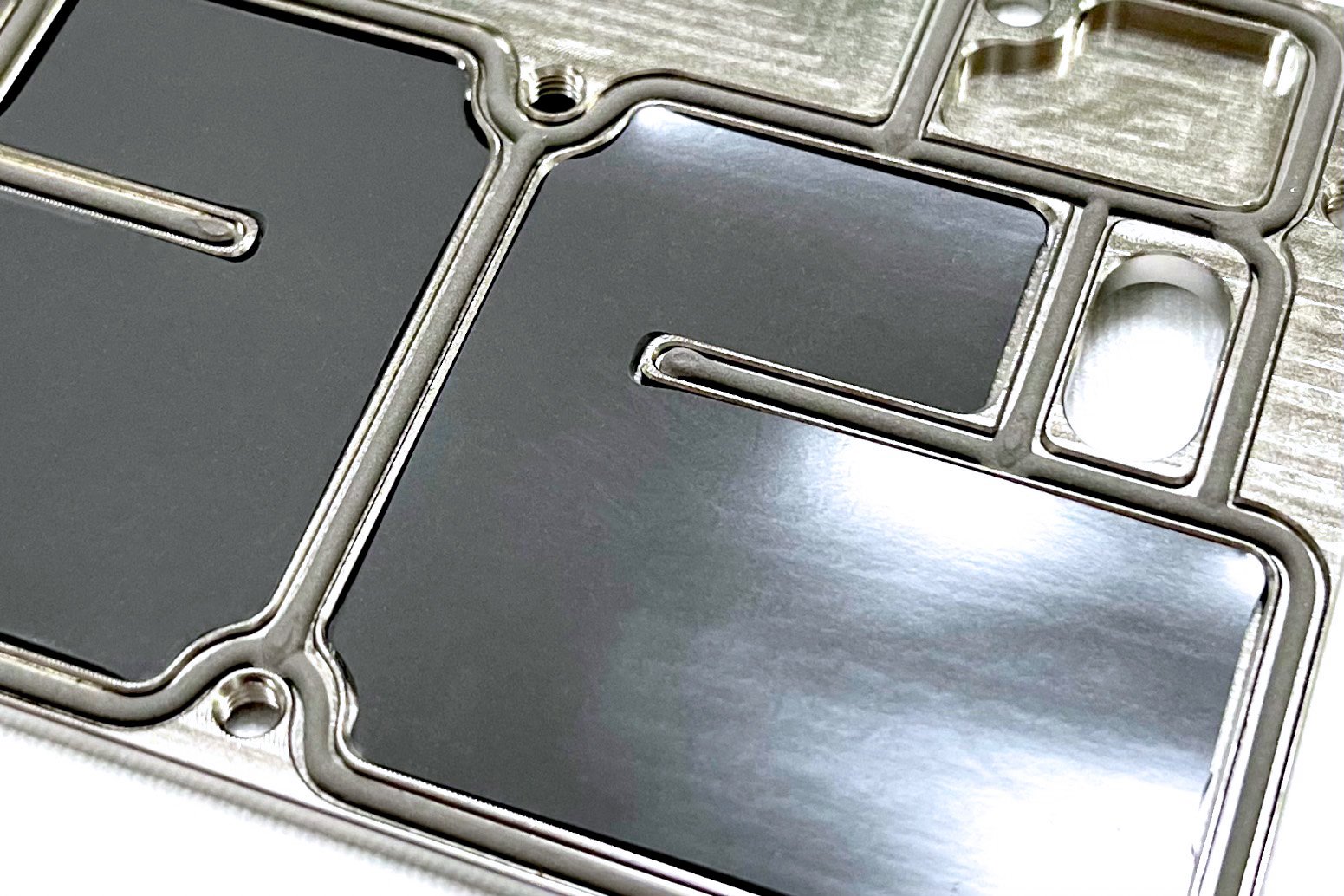

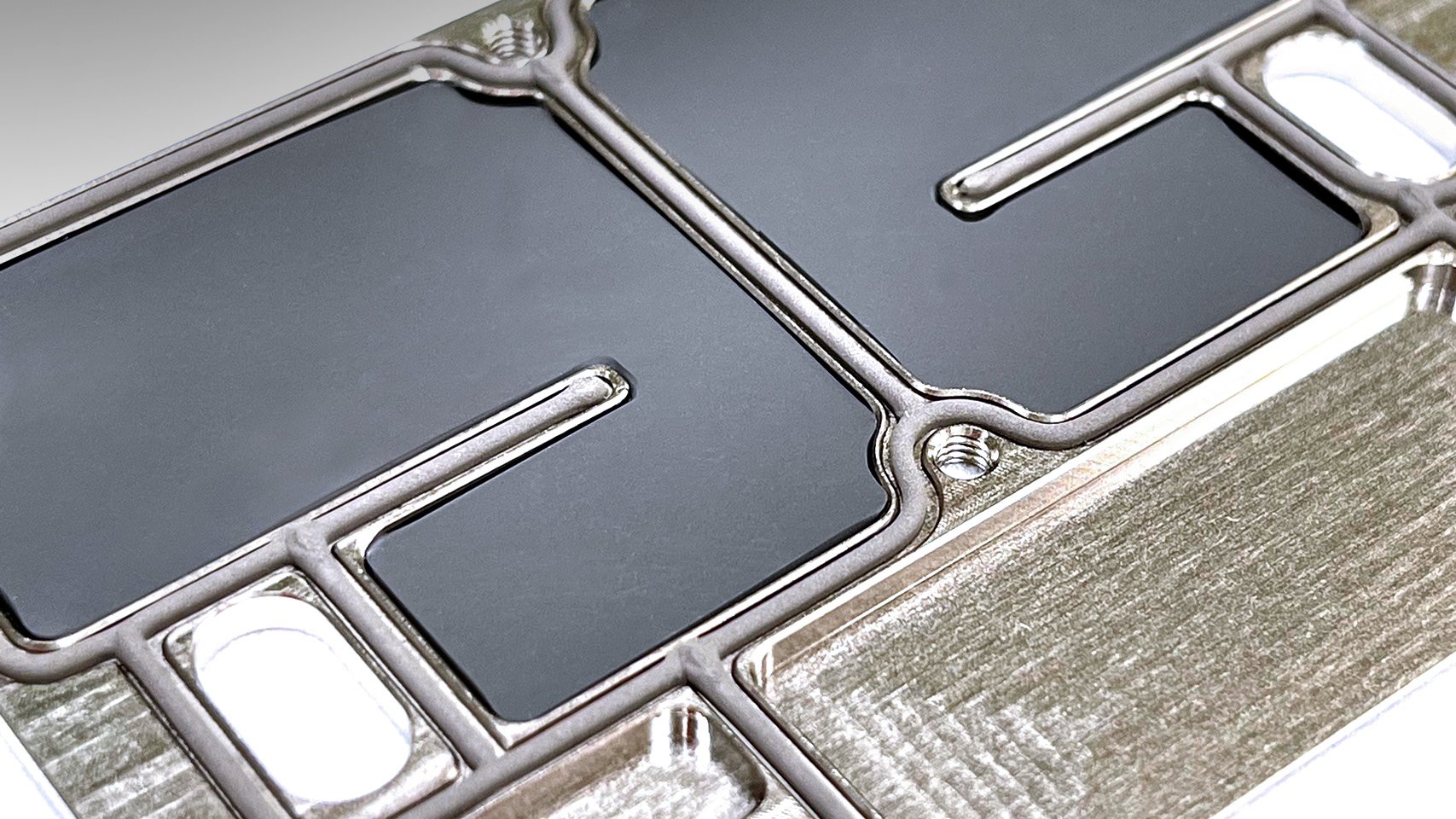

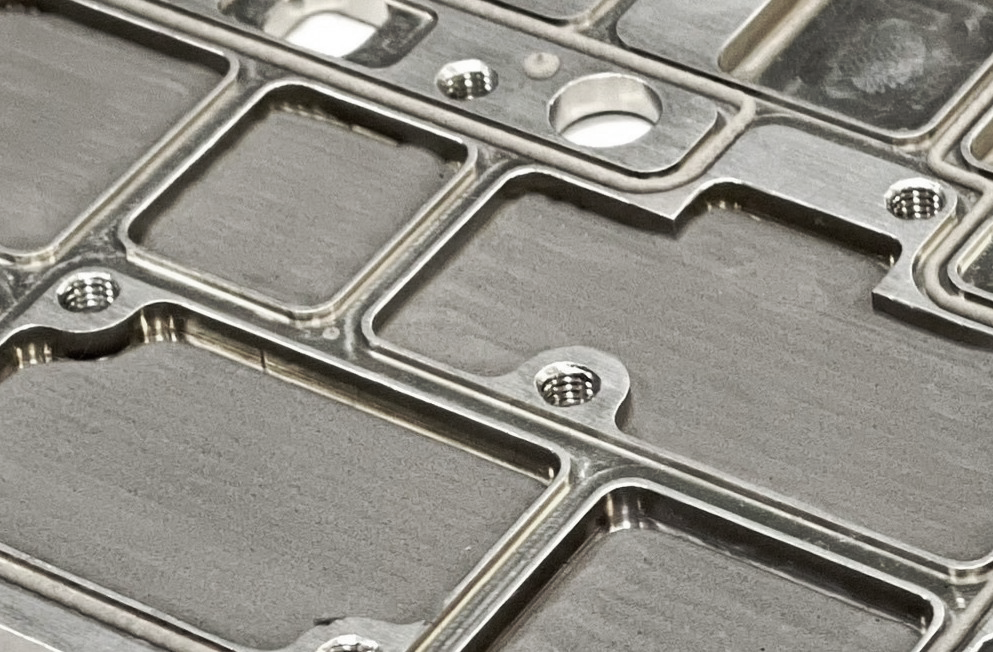

Dispensable Epoxy Absorbers

The automatically dispensed absorbers effectively reduce RF signals, suppress standing waves, and minimize RF noise. These epoxy-based absorbers adhere securely to metal surfaces, providing a permanent solution that eliminates the need for die-cutting or tape. With low outgassing properties, they meet NASA's stringent outgassing requirements when cured for an extended period. Additionally, they are electrically comparable to our cavity resonance sheet absorber products.

Our epoxy absorber comes in Commercial and High Performance grades to suit your needs:

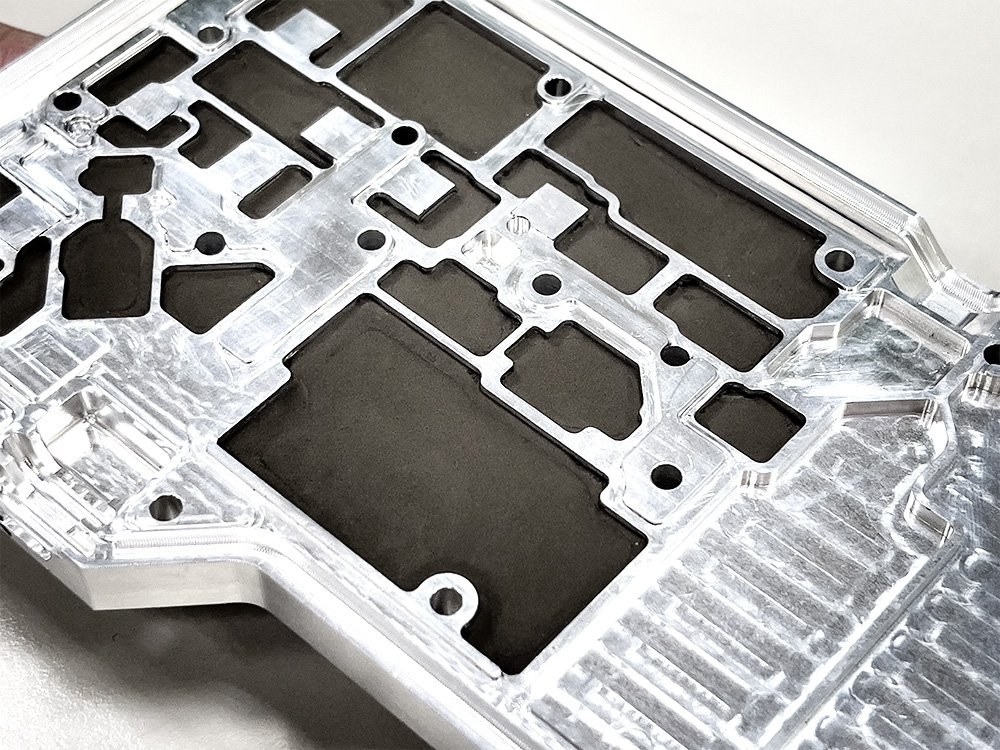

Cavity Resonance Absorber Pads

Our absorber pads survive outdoor exposure and have a wide working temperature range. Designed to be flexible, the absorber pads can be cut and fitted to compound curves. In addition, they have low outgassing and are RoHS compliant and halogen free. The absorber pads are a great cost-effective solution.

Our absorber pads range from Commercial to High Performance grades. Contact our sales team to learn which one best suits your product.