PHYSICAL VAPOR DEPOSITION

Cost-effective with speed and efficiency.

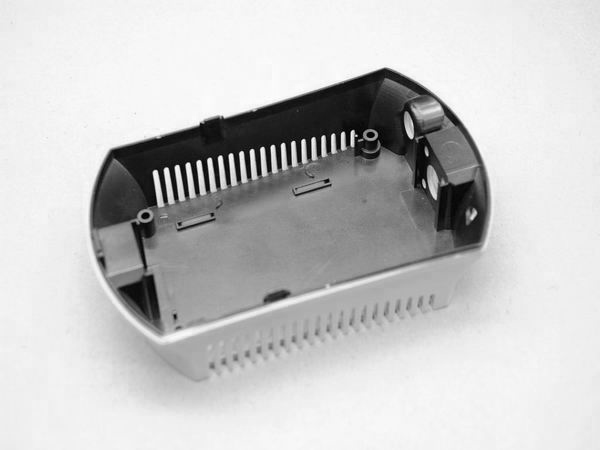

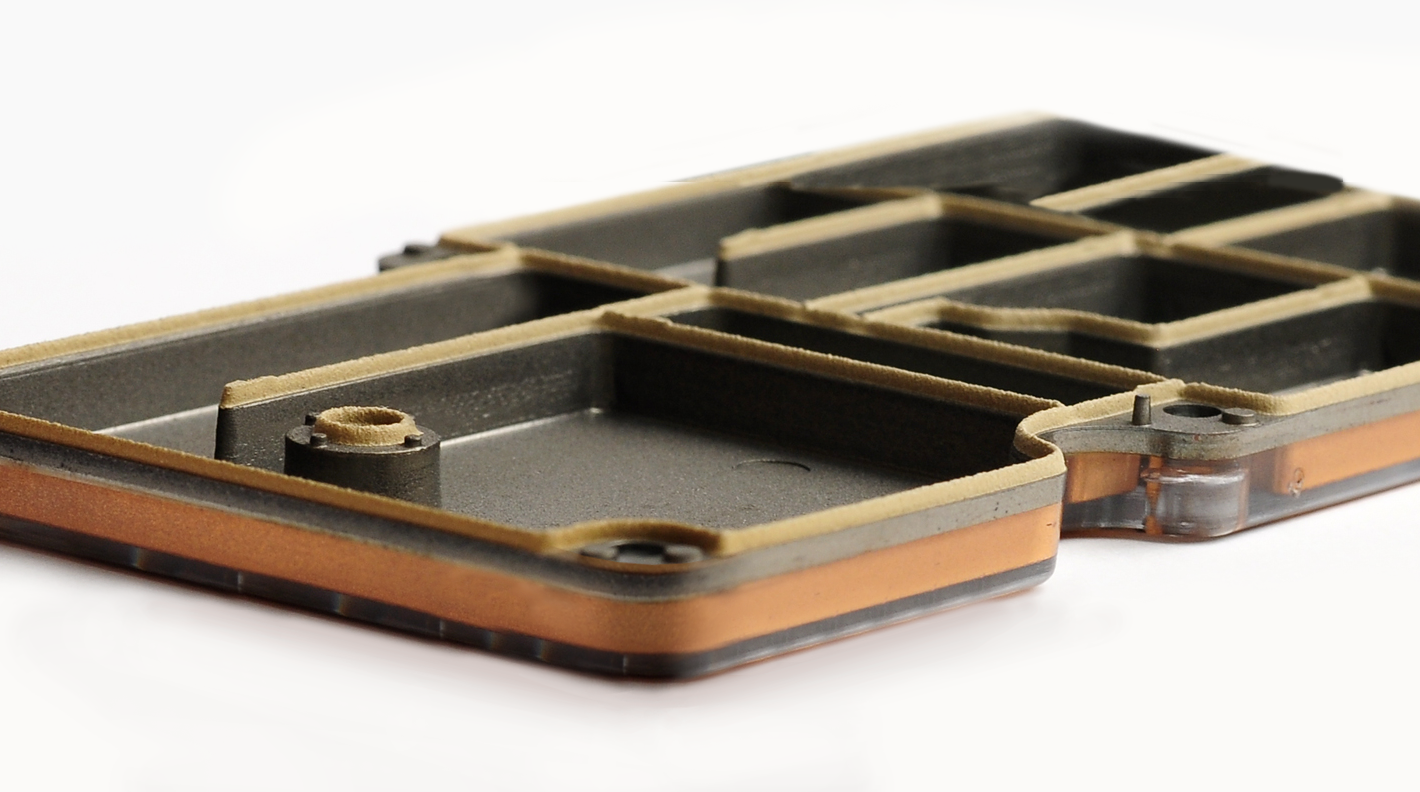

Vacuum Metallization, also known as Physical Vapor Deposition (PVD) and Plastic Metallization, is the process specifically designed for EMI shielding, where a metallic layer, such as titanium, copper, or aluminum is deposited onto a wide range of plastic housing, such as ABS, PC, PA6, PBT, PPA, PPS, PEI, PET, PSU or PEEK.

This process is a cost-effective way of shielding against electromagnetic interference, providing a wide range of material choices.

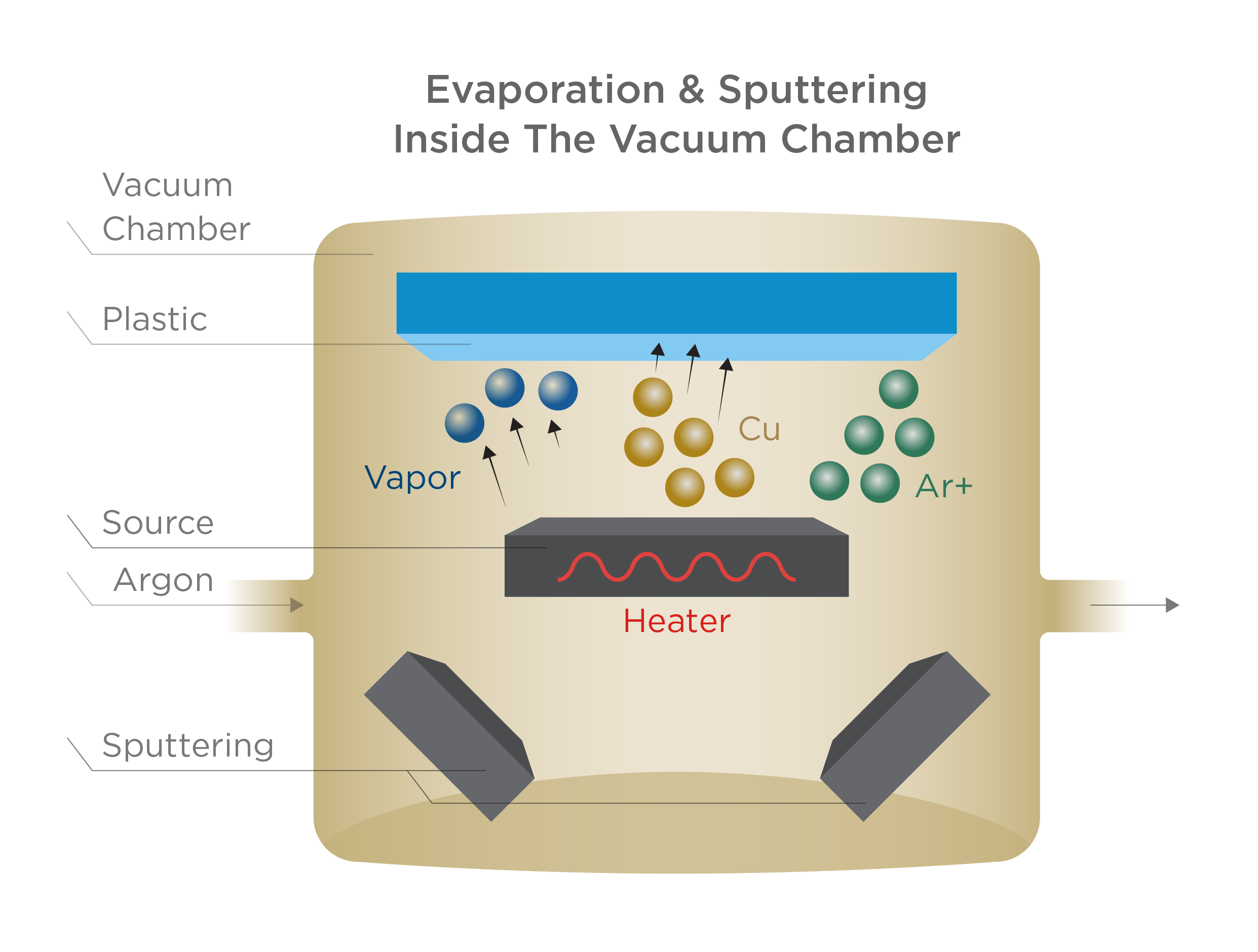

Metallization Within the Vacuum Chamber

Within the vacuum chamber, the metal is heated and vaporized, then impregnated onto the plastic housing.

Our facilities are uniquely equipped with Evaporation and Sputtering technologies, both are done in a single vacuum chamber.

This process produces a thicker shielding layer and higher level of accuracy across the production line, ensuring high quality end products while maximizing production yield.

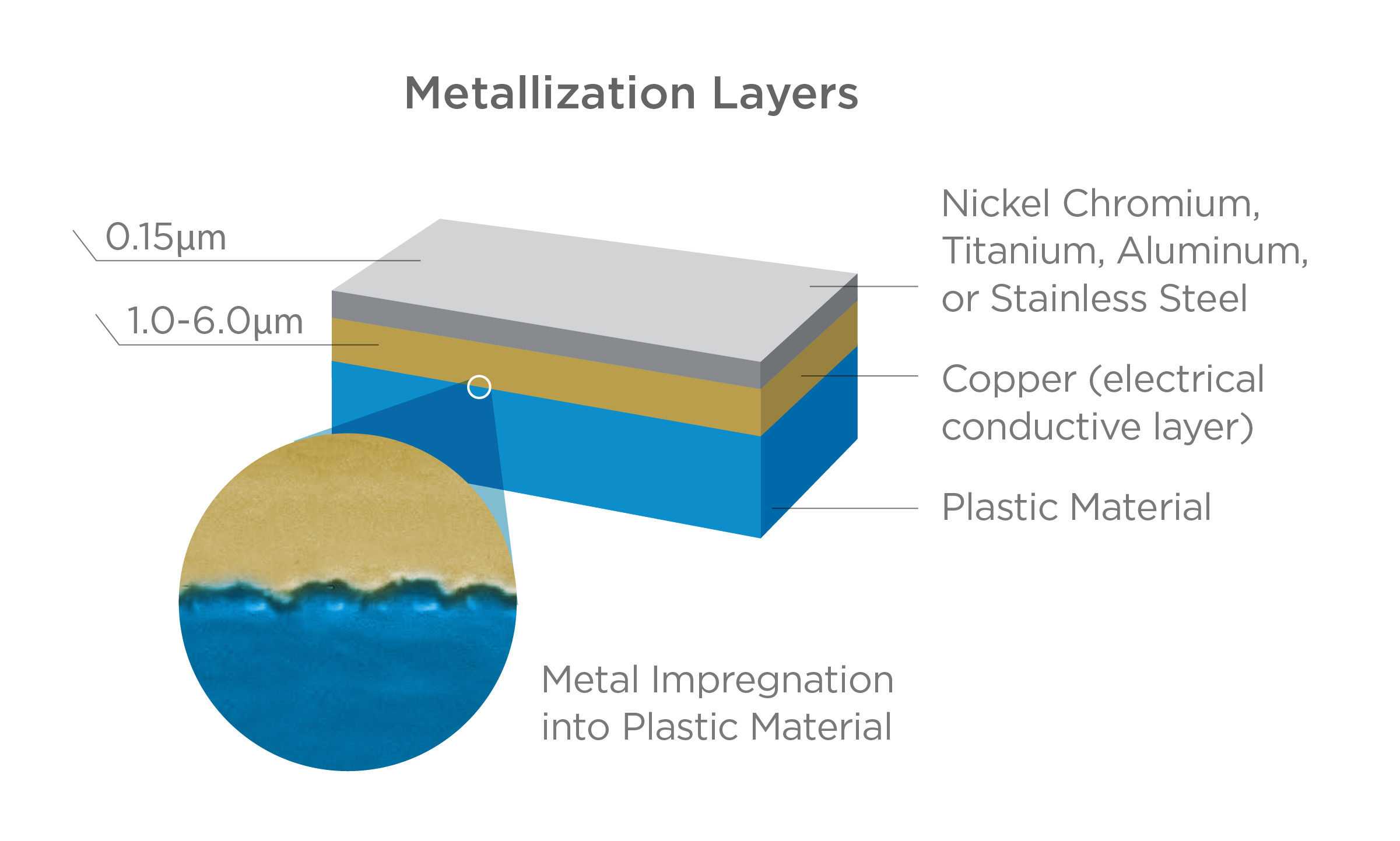

Coating Structures

The metallization by vacuum technology uses the condensation of a metal vapor coating the object. This vapor is generated within a vacuum and diffuses within the vacuum. The standard thickness of the metallic layer is 1.6 microns with the possibility of up to 10 microns.

Articles on Vacuum Metallization

Discover the latest innovations, trends, and insights in vacuum metallization. Stay up-to-date with expert knowledge and industry developments!

get in touch

We’re friendly and available to chat. Reach out to us anytime and we’ll happily answer your questions.

Technical FAQ

Here are a few commonly asked engineering and application questions about vacuum metallization (PVD):

-

Vacuum metallization—also known as physical vapor deposition (PVD)—is a vacuum process where a metal vapor condenses onto a substrate surface, forming a thin, bonded coating for EMI shielding, decorative or functional finishes.

-

In PVD, a solid metal source is vaporized in a vacuum (via evaporation, sputtering or arc), travels through the chamber, then condenses onto the part surface atom by atom to form a thin film.

-

PVD coatings can be applied to plastics, metals, ceramics and glass—using materials such as aluminum, titanium, alloys, nitrides or carbides—to provide wear resistance, EMI shielding, corrosion protection, or decorative finishes.

-

PVD coatings are typically harder, more corrosion‑resistant, and thinner than electroplating, operate at lower temperatures, offer precise thickness control, environmental benefits, and maintain dimensional tolerances.

-

Typical vacuum metallization (PVD) coatings range from about 0.05 µm to a few microns thick, depending on the application—thin decorative films may be <0.1 µm, while EMI or protective finishes often use 1–2 µm layers.